What are the Parts of the Bending Machine?

Understanding the components of a bending machine is essential for efficient metal processing. Bending machines play a crucial role in manufacturing, utilizing both hydraulic and mechanical systems to achieve precise bends. This article explores the working principles, key components, and the importance of maintenance, particularly focusing on bending machine molds.

Working Principles and Components

A bending machine operates primarily through hydraulic or mechanical systems, enhanced by CNC technology for precise control over bending angles and shapes. The main components of a bending machine include:

Frame: The sturdy structure that supports the entire machine.

Bed: The platform where the metal sheet is placed and secured for processing.

Ram: The movable part that applies force to bend the sheet, connected to hydraulic cylinders.

Dies: Tools that shape the metal during bending, with upper and lower dies working in tandem.

Hydraulic System: Provides the necessary power for the ram's movement through hydraulic cylinders and other components.

Electrical System: Controls various machine functions, including the movement of the ram and worktable.

CNC System: Automates operations and enhances production efficiency through programmed controls.

Maintenance of Consumable Parts

Regular inspection and maintenance of consumable parts are crucial for the bending machine's optimal performance and longevity. Key components that require attention include:

Dies: These parts are subject to wear from constant contact with metal sheets. Regular checks and replacements are necessary to maintain bending quality.

Hydraulic Cylinders: Under heavy pressure, these components can experience seal and piston rod wear, leading to leaks. Routine maintenance is essential to avoid operational issues.

Beams and Electrical Components: Structural integrity and functionality must be regularly assessed to prevent breakdowns.

Bending Machine Molds

The selection of mold materials is vital in the bending process. Common materials include:

High-Speed Tool Steel: Ideal for general metal sheets due to its wear resistance.

Alloy Tool Steel: Suitable for high-strength sheets, providing higher hardness.

Carbide: Offers exceptional hardness and is best for high-wear materials.

For complex bending tasks, custom molds are highly recommended. These molds not only improve production efficiency but also ensure high-quality outcomes.

Customization of Bending Molds

When designing custom molds, offering detailed specifications is essential. Key considerations include:

Bending Angles and Shapes: Precise angles are crucial for meeting production standards.

Material Characteristics: Understanding the properties of the metal sheet helps in choosing the right mold design.

Machine Specifications: Accurate information about the bending machine ensures molds fit correctly.

Moldes personalizados aumentam a adaptabilidade, otimizam os ciclos de produção e contribuem para uma qualidade superior do produto.

Conclusão

Em resumo, compreender os componentes de uma dobradeira, incluindo práticas de manutenção e personalização de moldes, é vital para o sucesso do processamento de metais. Ao se concentrar nesses aspectos, os fabricantes podem obter operações de dobra eficientes e precisas.

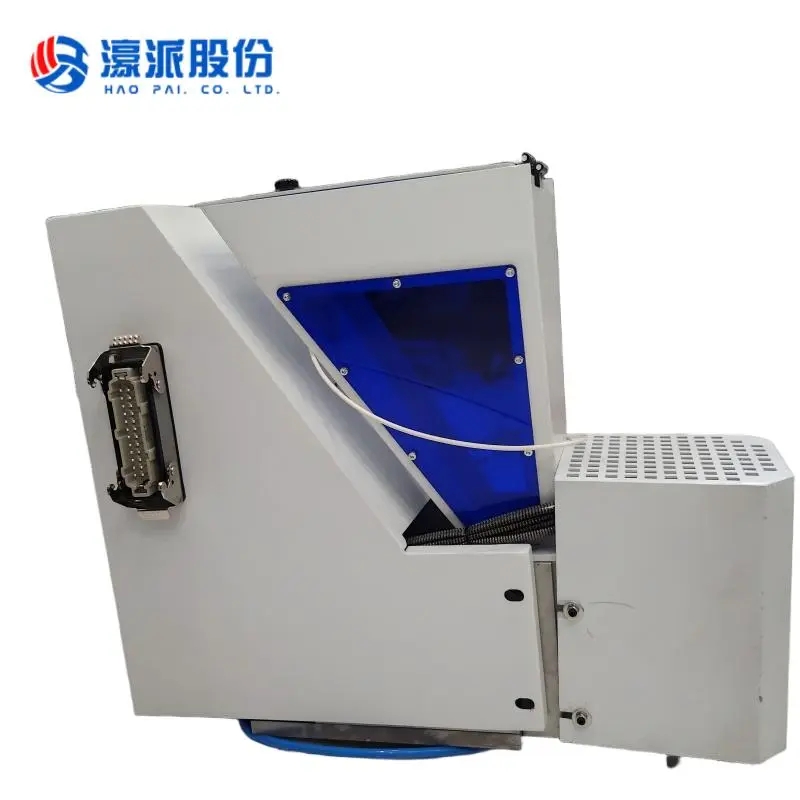

Para peças de máquinas industriais de alta qualidade, incluindoPeças para máquinas de colagem de bordas,Potes de cola para colagem de bordas,Rolos de cola para colagem de bordas,Unidades de pré-fusão, eEspalhadores de cola, considere a Foshan Haopai Electromechanical Equipment Co., Ltd. Com mais de 15 anos de experiência, nos dedicamos a fornecer produtos superiores para atender às suas necessidades de fabricação.